Inconel Is An Alloy Of Nickel Containing Chromium And Iron,Resistant To Corrosion At High Temperatures.Inconel Is A Family Of Austenite Nickel-Chromium Based On Super Alloys.

Inconel Is An Alloy Of Nickel Containing Chromium And Iron,Resistant To Corrosion At High Temperatures.Inconel Is A Family Of Austenite Nickel-Chromium Based On Super Alloys.

Manhar metal supply corporation deals in inconel grade 600, 601, 625, 718, 750, 800, 800h,825, 901.

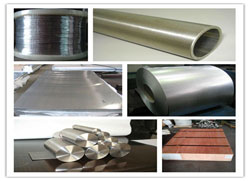

PRODUCTSVarious forms of inconel that we deal in are wire ,spring hard wire,fller wire,block, rod ,round bar,bright bar, rolled bar, square , hex ,strips, flat,foil, sheet ,coil,slitting coil, plate, tubes, pipe,seamless pipes , capillary tubes ,fittings, elbow,tee, reducer, ,union coupling,nipple, flanges, fastner, nut bolt , screwed fittings, forge fittings,ferrule fittings ,buttweld fittings , wire mesh , coupling, ,crucibal, ,scrap, , nozzles ,ingot,ring,bushes,disc,,rectangles

PROPERTIESInconel Alloys Are Oxidation And Corrosion Resistant Materials Well Suited For Service In Extreme Environments Subjected To Pressure And Heat.When Heated,Inconel Forms A Thick,Stable,Passivating,Oxide Layer Protecting The Surface From The Further Attack.Inconel Retains Strength Over A Wide Temperature Range,Attractive For High Temperature Applications Where Aluminium And Steel Would Succumb To Creeps A Result Of Thermally Induced Crystal Vacancies.Inconel’s High Temperature Strength Is Developed By Solid Solution Strengthening Or Precipitation Strengthening, Depending On The Alloy.Inconel Alloys Are Typically Used In High Temperature Applications.It Is Sometimes Referred To In English As “Inco” (Or Occasionally “Incone”). Common Trade Names For Inconel 625, Hayness 625, Nickel Vac 625.

USESInconel Is Often Encountered In Extreme Environments. It Is Common In Gas Turbine Blades, Seals, And Combustors, As Well As Turbocharger Motors And Seals, Electric Submersible Well Pump Motor Shafts, High Temperature Fastners, Chemical Processing And Pressure Vessels, Heat Exchanger Tubing, Steam Generators And Core Components In Nuclear Pressurized Water Reactors,Natural Gas Processing With Contaminants Such As H2s Co2 , Firearm And Suppressor Blast Baffles,And Formula One, Nascar And Apr, Llc Exhaust Systems. It Is Also Used In The Turbo System Of The 3rd Generation Mazda Rx7, And The Exhaust Systems Of High Powered Rotary Engined Norton Motorcycles Where Exhaust Systems Temperatures Reach More Than 1,000˚C, Inconel Is Increasingly Used In The Boilers Of Waste Incinerators. Inconel 718 Is Commonly Used For Cryogenic Storage Tanks, Downhole Shafts And Wellhead Points.

Rolled Inconel Was Frequently Used As The Recording Medium By Engraving In Black,Box Recorders On Aircraft. Alternatives To The Use Of Inconel In Chemical Applications Such As Scrubbers, Columns, Reactors, And Pipes Are Hastalloy, Perfluoroalkoxy(Pfa)Lined Carbon Steel Or Fiber Reinforced Plastic.The Exhaust Valves On Nhra Top Fuel And Funny Car Drag Racing Engines Are Made Of Inconel.Inconel Is Also Used In Manufacture Of Exhaust Valves In High Performance Aftermarket Turbo And Supercharged Mazda Miata Engine Builds(Se Flying Miata Inc)

PRODUCT INFO:-Alloy 600 Has Excellent Resistance To Oxidation At Temperature Upto 1175 Degree Celsius And Is Also Resistant To A Variety Of Corrosive Media. It Retains Its High Strength Up To About 650 Degree Celsius. Even At Lowest Temperatures, Alloy 600 Has Good Mechanical Properties. Due To Its Resistance To Chloride Stress Corrosion Cracking, Alloy 600 Is Employed In Components Of Power Plants. This Grade Can Be Welded Without Thermal Retreatmnt.

INCONEL 601 (ALLOY 601):Alloy 601 Has Very Good Properties At High Temperature And Is Oxidation Resistant As Well As Scale Resistant At Temperatures Of Up To 1250 Degree Celsius. The High Chromium Content Results In Good Resistance Against Oxidation, Carburisation And Sulfurous Media. The Aluminium And Nickelcontent Result In A Further Improvement Of The Oxidation Resistance.

INCONEL 625(ALLOY 625):Excellent Corrosion Resistance With High Strength And Ductiliy At Temperature Upto 700 Degree Celsius Applicable Upto 1100 Degree Celsius Alloy 625 Is Weldable Without Thermal Retreament.

INCONEL 800(H) (ALLOY 800 H):This Alloy Is Resisitant To Corrosion Resulting From Hydrogen And Hydrogen Sulfide As Well As To Stress Corrosion Cracking.It Is Highly Heat Resistant And Insensitive To The Separation Of Sigma Phase.Alloy 800 H With Controlled Carbon Content Improves Futhermore The Creep Strength Depending On Time In Solution Annealed Condition.

INCONEL 825 (ALLOY 825) :Resistance To Sulfuric Acid, Phosphoric Acid Solvents And Sea Water As Well As To Many Oxidising Chemicals.Alloy 825 Has Good Resistance To Reducing Acid. It Can Be Employed Without Thermal Treatment After The Welding Process.

HASTALLOY C-276 (ALLOY C-276) :Today probably one of the best and manifold alloys 0n the market hence employed in extreme corrosive reducing and oxidising applications. alloy c-726 has excellent resistance to strong oxidizing media contaminated by chloride, dry chloride acid, formate acid, acetic acid, acetic hydride solution, sea water solutions and saline solutions. the alloy is resistant to the corrosive influence of wet hydrochloride acid, hydrochloride dioxide solutions.

HASTALLOY C-4 (ALLOY C-4 :Excellent resistance against strong oxidising agents, hot contaminated miniral acids,solvent, chlorine and media contaminated by chlorine(organic and inroganic), dry chloric acid, formic acid, acetic acid, acetic hyride solutions, sea water solutions, and saline solutions. this alloy has high ductility and corrosive resistance even in temperature range of 650-1040 degree celsius.alloy c-4 is resistant against the formation of grain boundary carbides and can thus be used in most cases without heat-treatment after welding.

INCOLLOY DS (ALLOY DS):Alloy ds is a heat resistant ni-cr-fe alloy with si addition for the employment at high temperatures where sufficient strength and corrosive resistance are required. alloy ds is heat-resistant upto 1100 degree celsius when in fresh air. this alloy is especially resistant against changing oxidising / reducing conditions as well as the formation of sigma phase in the critical temperature range of 590-870 degree celsius . furthermore it is green rot. due to high strength and heat resistance to alloy ds, smaller sections than usual can be manufactured from this material.

ALLOY 20 :Alloy 20 is a high –alloyed stainless steel. its corrosion properties surpass those of usual stainless qualities. for example .alloy 20 has excellent stress corrosion to boiling 20-40 % sulfuric acid. although alloy 20 was originally developed for usage in sulfuric environment, its range application has been steadily extended and today also includes machining of artificial rubber, plastic, synthetic fibre etc.in pharmaceutical and food producing application,where purity has to be guaranteed, alloy 20 is employed to prevent metallic contamination. the most important advantages of this grade are its excellent mechanical properties as well as its comparatively easy machine ability.

MONEL 400(ALLOY 400), MONEL K500 (ALLOY K-500):About monel 400: alloy 400 is especially resistant to saline and other acids in ventilated condition.it is successfully employed in the salt winning process. alloy 400 is especially suited for employment in the sea barkage water at high speed, where resistance against cavitation and erosion is of great importance. this alloy is very resistant to solvents, glass-etching agents, sulfuric and other acids and virtually to all alkalis. this grade is not sensitive to stress corrosion cracking in oxidizing media. alloy 400 can be employed at temperatures up to 550 degree celsius.

ABOUT MONEL-500:An age-hardening alloy with the same corrosion resistance as alloy 400, though with increased tensile strength and hardness. alloy k-500 retains its strength upto temperature of about 650 degree celsius.

MONEL K-500 (ALLOY K-500):An age-hardening alloy with the same corrosion resistance as alloy 400, though with increased tensile strength and hardness.alloy k-500 retains its strength up to temperature of about 650 degree celsius.